ECOVIZ KFT.

Water treatment and environmental technologies

ADVANCE 200® GAS-FEED Chlorination equipment

ECOVIZ KFT has been manufacturing rightly reputed ADVANCE 200® gas chlorination equipment since 1972. Considering the quality, safety and convenience, ECOVIZ KFT’s chlorinators rank among the best designs ever made. Units are being producedin the dosing range from 10 gr/h up 150 kg/hr (7500 PPD). All Series 200, 202, 203, 204, 206 and 207 vacuum regulators can all be offered in wall mounting versions.

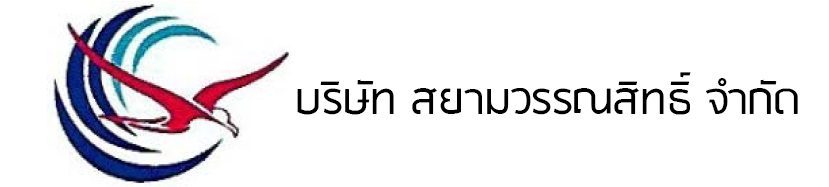

Wall Mounted Vacuum Regulators

ADVANCE 200® vacuum regulators below 10 kg/hr (500 PPD) capacity can all be fitted for wall mounting. The vacuum regulator is mounted onto a panel with four wall mounting holes. Vacuum regulators include silver rate valve, PTFE Diaphragm Tantaloy tungsten springs to ensure maximum safety.

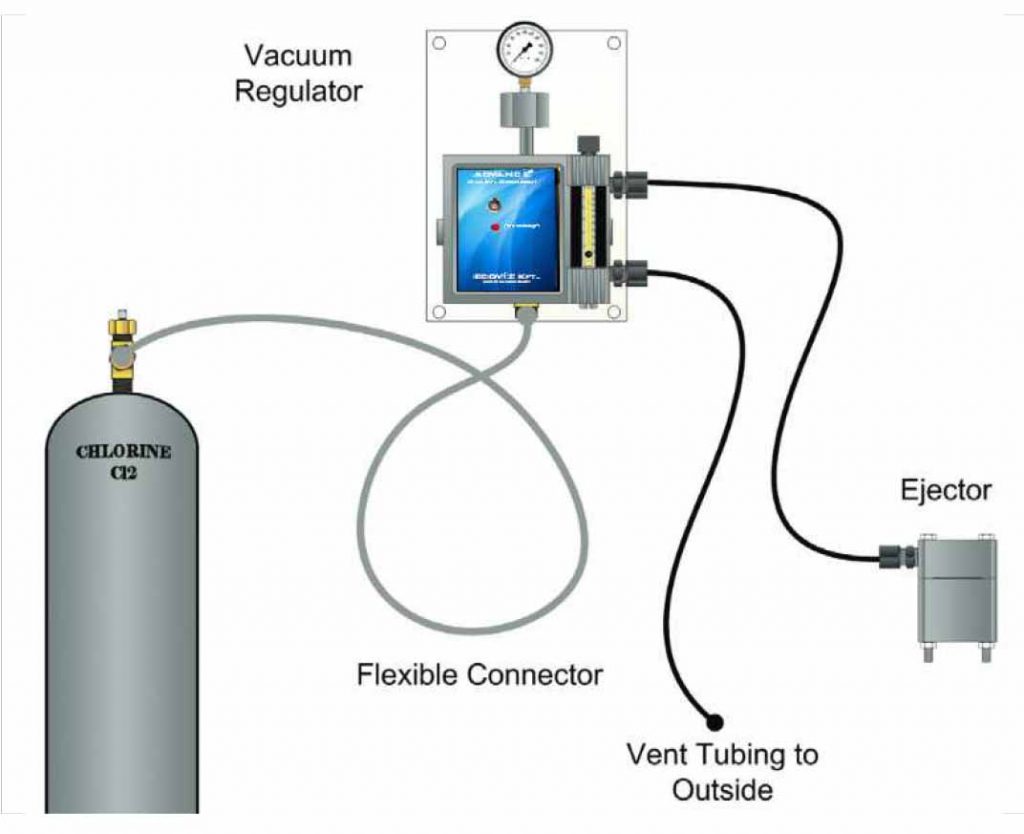

Drip Leg Requirement

For use with separated chlorine storage containers the wall

mounted vacuum regulator must be fitted with a drip leg and heater. A small amount of liquid chlorine always comes out of full bottles /barrels the first time they are opened. This liquid will cause damage if allowed to enter the vacuum regulator. Therefore, a drip leg with continuously energized heater must be used for better chlorine evaporation during operation.

Chlorine Gas Inlet Connection

Each wall mounted vacuum regulator requires a flexible

connector with threaded fittings. Flexible connectors are available in 2, 3, 4, 5, 7 meter lengths

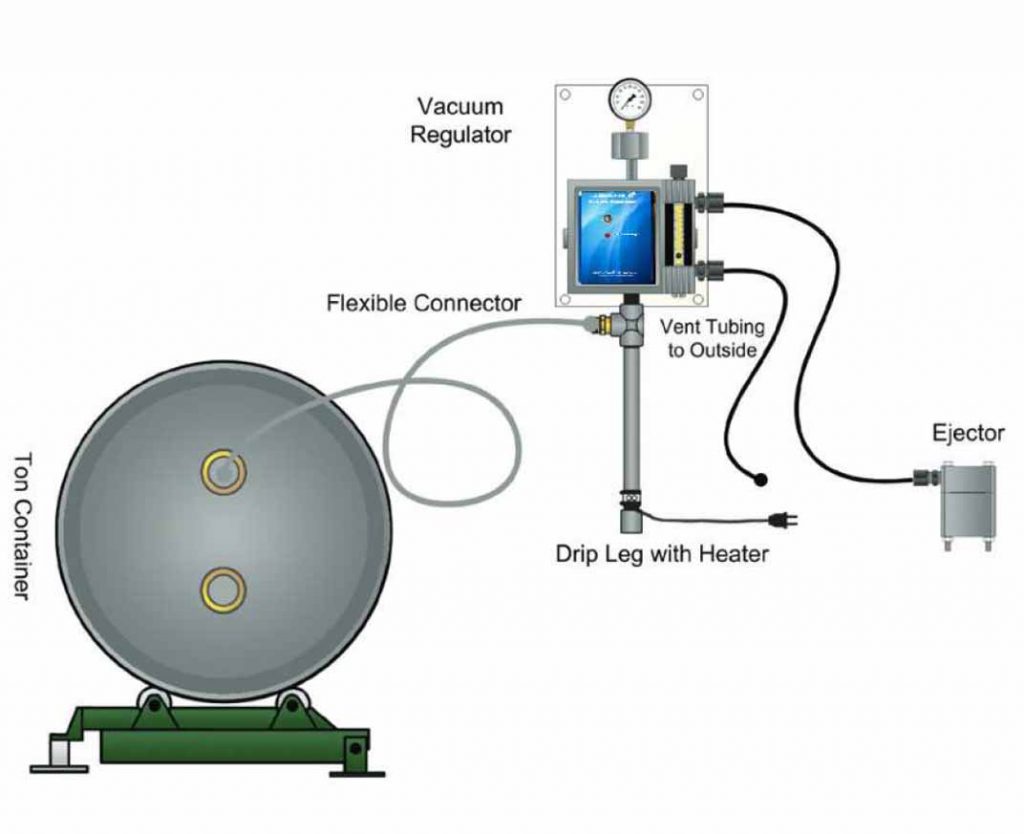

If only one chlorine cylinder or ton container is being used,

then the flexible connector can be directly connected from the wall mounted vacuum regulator to the chlorine cylinder or chlorine container (chlorine valve). However, if more than one chlorine cylinder or barrel is to feed one vacuum regulator, then additional manifolds must be installed.

Specifications

Vacuum Regulator

- Each regulator has a spring opposed diaphragm which controls

vacuum and closes tight upon loss of vacuum. - Each regulator incorporates a pressure relief (vent) valve with

separate ports for chlorine feed and chlorine vent. - Connections are provided for tubing vented gas away from the

pressure relief (vent) port of each vacuum regulator to atmosphere

outside the building. The outside end of the vent tubing shall be

equipped with an insect sieve. - Each regulator is equipped with an inlet filter to remove

particulate matter from the gas before it enters the inlet safety valve. - Each regulator can optionally include a flow meter tube to indicate

feed rate and which cylinder is in use. - Each regulator include a mechanism to indicate when the chlorine

gas cylinder is empty and requires replacement.

Wall mounted design

- The vacuum regulator(s) can be bracketed to a panel for wall

mounting. The vacuum regulator can be combined with a diaphragm

protected chlorine gas pressure gauge, if required.

Wall Mounting Option for Ton Container Installations

- The vacuum regulators can be bracketed to a panel for wall mounting.

Up on request, the assembly can be combined with a diaphragm protected

chlorine gas pressure gauge. - The wall mounting vacuum regulator assembly shall include a vertical collector

pipe (drip leg) with a heating pad to trap and evaporate the liquid chlorine and

prevent it from entering the vacuum regulator.

Ejector Options

- The ejectors can be ordered with two identical spring loaded check

valves for additional back flow protection. - For back pressures exceeding 145 psi (10 kg/cm2) the ejectors should

be fitted with high pressure support plates.

Ejector

- The ejectors are water operated designs types working after

the Venturi-pipe principle.

The ejector provides the operating vacuum for the whole

chlorination system. - The ejector s include a spring loaded, normally closed check

valve to prevent the backflow of water into the chlorinator.

The check valve is suitable for back pressures up to a minimum

of 145 psi (10 kg/cm2). - Ejector check valve closes automatically upon the loss of vacuum

in the Ejector.

Automatic Switchover Module

- A separate mechanical device provides the automatic switching

from empty cylinder to the standby cylinder. The switchover module

is suitable for wall mounting. A pair of ADVANCE 200 vacuum

regulators will directly perform the vacuum switchover function.

Rotameter

- A gas flow meter can be provided to indicate the gas flow rate.The gas flow meter is suitable for wall mounting.

- This gas flow meter includes a control valve for manual

feed rate adjustment.